Stator Cooling System Provide Qualfied Cooling Water for Production

Stator cooling systems are crucial in various industrial applications, especially in energy generation. The water in these systems is circulated to absorb heat from equipment or buildings and is then cooled back down. Proper treatment of stator cooling water is essential to prevent scaling, corrosion, and microbial growth in the system, ensuring efficient operation and extending equipment lifespan. Resins, particularly ion exchange resins, play a significant role in maintaining the quality of stator cooling water.

Resin Options

We supply the best ion exchange resin types for stator cooling water treatment applications. According to the selected process, you can choose the following resin types for your water treatment applications.

- Strong Acid Cation Exchange Resins. Used in the softening system to remove hardness ions such as calcium (Ca2+) and magnesium (Mg2+) from the water, which would otherwise cause scale formation in cooling system, especially in heat exchangers and cooling towers.

- Mixed Bed Resins. Combine both cation and anion exchange resin in one vessel to complete deionization and pH control.

How Resin Based Stator Cooing System Works?

Depending on the water quality requirements, three common mixed bed designs are used in stator cooling water treatment: H/OH Mixed Bed, H/OH Mixed Bed + SAC-H, and H/OH Mixed Bed + Na/OH Mixed Bed. Each design has its own advantages and is suitable for different cooling water systems.

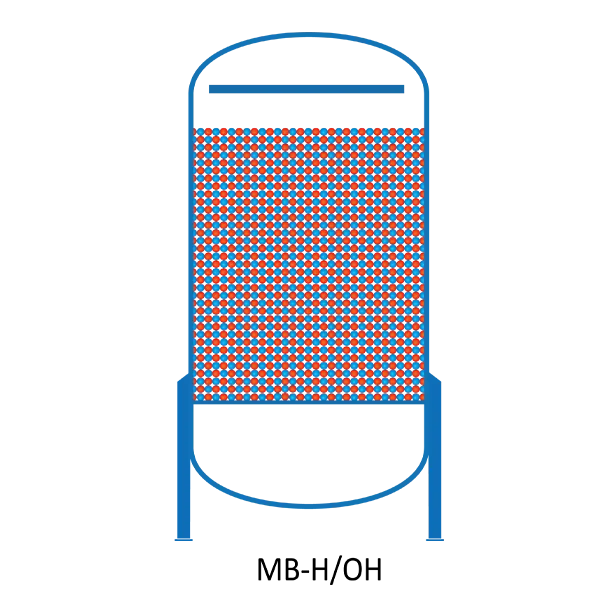

H/OH Mixed Bed

The H/OH mixed bed consists of strong acid cation exchange resin (H form) and strong base anion exchange resin (OH form). The cation resin exchanges cations such as calcium, sodium, and copper for hydrogen ions (H+), while the anion resin exchanges anions such as chloride and sulfate for hydroxide ions (OH-). This design effectively adjusts the pH, lowers conductivity, and removes copper ions.

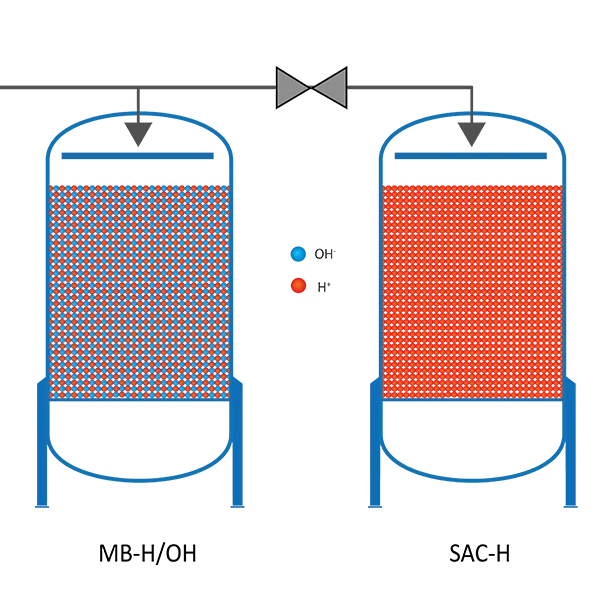

H/OH Mixed Bed + SAC-H

In this design, the H/OH mixed bed is supplemented with Strong Acid Cation (SAC-H) resin. SAC-H resin is highly effective at removing hardness ions such as calcium and magnesium, while also helping to remove copper ions by adjusting the pH.

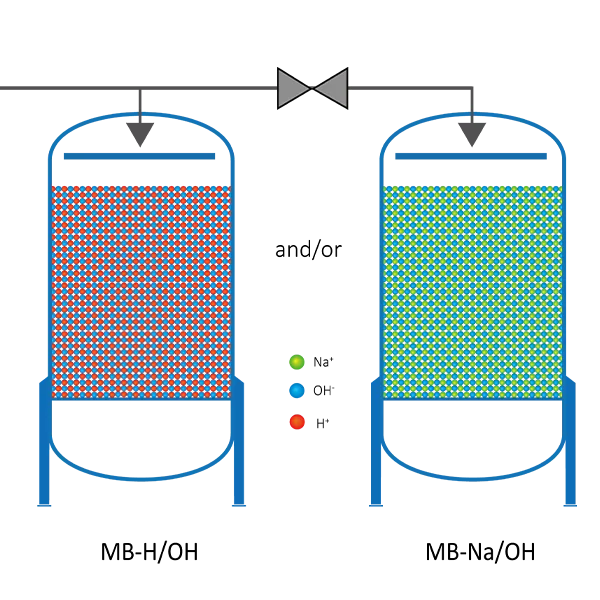

H/OH Mixed Bed + Na/OH Mixed Bed

This design combines an H/OH mixed bed with a Na/OH mixed bed. The H/OH mixed bed adjusts the pH and removes ions, while the Na/OH mixed bed, with sodium-based cation exchange resins, removes sodium ions and maintains an alkaline pH. The Na/OH mixed bed also helps control conductivity by further removing ions.

Industries and Specific Applications of Resin-Based Stator Cooling System

Power Generation Industry

- Generator Cooling: Stator cooling water directly cools the stator windings, maintaining their operating temperature and preventing overheating.

- Heat Exchange Systems: Cooling water is used in large-scale heat exchangers to improve efficiency and prevent system overheating.

- Boiler Water Treatment: Cooling water is used in boilers to remove corrosive ions such as copper ions, preventing damage to the boiler tubes.

Chemical Industry

- Reactor Cooling: Cooling water helps maintain the temperature in chemical reactors, ensuring that reactions proceed at optimal conditions.

- Heat Exchange Systems: Cooling water is used to efficiently transfer heat from reactors and other equipment, improving energy efficiency and preventing overheating.

Oil and Gas Industry

- Drilling Equipment Cooling: Cooling water helps maintain drilling equipment in a high-temperature environment, preventing overheating and extending the life of machinery.

- Pipeline Cooling: Cooling systems are essential in the transportation of oil and gas to ensure that pipelines do not overheat or corrode.

Metallurgical Industry

- Furnace Cooling: High-temperature furnaces used for metal smelting require cooling water to prevent overheating and damage to the equipment.

- Heat Exchanger Cooling: During metal processing, cooling water is used in heat exchangers to efficiently transfer heat away from molten metal and prevent damage to the equipment.

Semiconductor Industry

- Laser Cooling: Cooling water is used to cool lasers in semiconductor fabrication, preventing performance degradation due to high temperatures.

- Cleaning and Drying: Cooling water is used in the cleaning and drying processes during semiconductor production, where high water quality is essential to avoid contamination.

- Temperature Control in Wafer Production: Cooling water maintains the proper temperature in wafer processing equipment to ensure the high quality and precision of semiconductor products.

Food and Beverage Industry

- Fermentation Cooling: In brewing or dairy production, cooling water regulates fermentation temperatures to ensure the quality of the final product.

- Production Equipment Cooling: Cooling systems help maintain the temperature of machines involved in food processing, preventing overheating and ensuring efficient operation.

- Bottle and Packaging Cooling: During beverage bottling or food packaging, cooling water helps maintain the required temperatures, ensuring product safety and quality.

Need Any Help?

Need Any Help?

No matter guides, inquiry or assistance, our experts are ready to serve you.