Efficient Industrial Water Softening: Principles and Applications

Water softening is an essential step in industrial water treatment. Natural water often contains high concentrations of calcium (Ca2+) and magnesium (Mg2+) ions, which cause water hardness. By softening water, industries can minimize these issues, ensuring stable equipment performance, extended lifespan, and improved operational efficiency.

Resins, especial strong acid cation resins, reduce the concentration of calcium and magnesium by ion exchange technology, so that the hardness of water is controlled less than 50 mg/L (CaCO3) to guarantee effective industrial production

Resin Options

We supply the best ion exchange resin types for water softening applications. According to the selected softening process, you can choose the following resin types for your water treatment applications.

How Resin Based Softening Works?

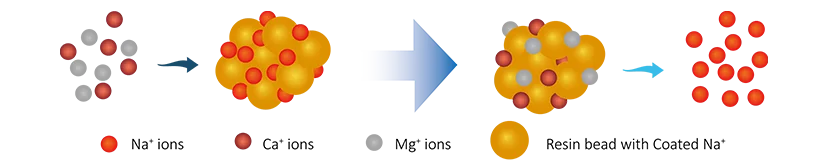

In the softening process, ion exchange resin is the key component used to remove hardness ions. The resin works by exchanging ions in the water, specifically replacing calcium and magnesium ions with sodium ions, thus reducing water hardness.

Softening Process: Cation Exchange Reaction

When hard water flows through sodium-based cation exchange resin (R-Na), the following reactions occur:

2R−Na + Ca2+ → R2−Ca + 2Na+

2R−Na + Mg2+ → R2−Mg + 2Na+

In that:

- R-Na: Represents the resin base (R) carrying sodium ions

- Ca2+ / Mg2+: Hardness ions in water

- R2-Ca / R2-Mg: Resin loaded with calcium or magnesium ions after exchange

- Na+: Sodium ions released into the water

This process reduces water hardness, ensuring soft water for industrial applications.

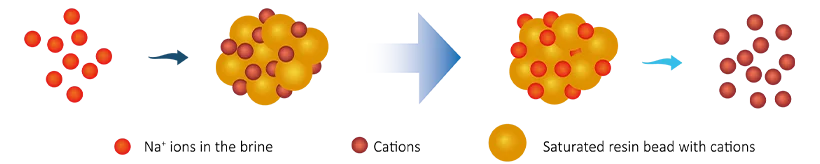

Regeneration Process: Restoring Resin Capacity

When the resin becomes saturated with calcium and magnesium ions, it is regenerated using a salt (NaCl) solution:

R2−Ca + 2NaCl → 2R−Na + CaCl2

R2−Mg + 2NaCl → 2R−Na + MgCl2

In that:

- NaCl: The regenerating salt solution that provides sodium ions

- CaCl2 / MgCl2: Waste product containing removed hardness ions

- R-Na: Regenerated resin ready for reuse in softening

Regeneration restores the resin's ion exchange capacity, ensuring cost-effective and sustainable operation.

Industries and Specific Applications of Resin-Based Water Softening

Energy and Power Generation

- Boiler feedwater treatment. Softened water is essential for preventing scale formation in boilers, improving thermal efficiency, and reducing energy consumption and protects turbines and heat exchangers from corrosion and scaling.

Food and Beverage Industry

- Beverage Production: Ensures the water used in brewing, bottling, and other processes is free from hardness ions, preserving flavor and quality.

- Food Processing: Provides consistent water quality for cooking, cleaning, and sterilization processes.

- Steam Generation: Softened water generates high-quality steam for heating and sterilization without scaling.

Oil and Gas Industry

- Boiler Water Softening: Protects heat exchangers and steam injectors from scaling in upstream and downstream operations.

- Process Water: Prevents scaling in separation and refining units, ensuring efficient operations.

Electronics and Semiconductor Industry

- Pre-treatment for ultrapure water systems. Softened water serves as the first step in producing ultrapure water for semiconductor and electronics manufacturing processes, preventing damage caused by hardness ions.

Chemical Manufacturing

- In chemical reactions, softened water prevents scaling in reactors and pipelines, ensuring stable operation.

- Used for preparing chemical solutions and dilutions that require precise water quality.

Textile and Dyeing Industry

- Dyeing Process: Softened water prevents interference from hardness ions, resulting in vibrant and consistent fabric colors.

- Washing and Finishing: Ensures high-quality fabric washing and finishing processes without mineral residues.

Paper and Pulp Industry

- Softened water enhances the quality of pulp processing and paper production by preventing scaling in machinery.

- Reduces downtime caused by maintenance and cleaning due to scale buildup.

Need Any Help?

Need Any Help?

No matter guides, inquiry or assistance, our experts are ready to serve you.